Master formula record (MFR) is a master document for any pharmaceutical product. It contains all information about the manufacturing process for the product. MFR is prepared by the research and development team of the company and all other documents like BMR and BPR are prepared using MFR by the manufacturing units.

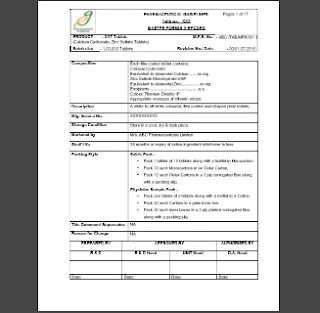

1. Product Details: First of all on the first page following details about the product are added.

Name, logo and address of the manufacturing company

Dosage form name

Brand name

Generic name

Product code

Label claim of all ingredients

Product description

Batch size

Pack size and packing style

Shelf life

Storage conditions

MFR number and date

Supersede MFR number and date

Effective batch number

Authorization by the production and quality assurance head

2. Flow Chart: Steps of the manufacturing process to be monitored. Flowchart of the material movement from dispensing to the final product to stores.

3. Equipment: Create a list of all required equipment and machines required in the manufacturing process with their capacity.

4. Special instructions: Write down the precautions special instructions to follow during the product manufacturing and packing and these should also be added in the batch manufacturing formula. Batch manufacturing formula should include the following.

Name of ingredients with test reference (As IP, BP, USP etc.)

Quantity to be added

Overages to be added (%)

5. Calculations: Include the calculation steps of all active materials to get the 100% of the active material. The calculation shall be done using water content or LOD to get 100% potency.

6. Manufacturing Process: Write all steps in all stages of the manufacturing process. All process steps like shifting, milling, mixing, lubricating, granulation, compression and coating should be written in detail including the process time and yield. Include atmospheric conditions as temperature, humidity, and storage conditions for every step.

7. Packing Process: List of all packing materials with their quantity is written. Line clearance, reconciliation of printed and unprinted packing materials should be included in details.

8. Yield: Include the theoretical, actual yield and acceptance limit of the batch.

The detail given above should be included in a general master formula record. Other details should be added as per company requirements in the master formula record.

I liked this very much. It just came to me in right time when I was looking for such directives on this subject. Thank u very Much

ReplyDeletenice dear sir its i am very thankful to you for valuable information rajpar fayaz

ReplyDeleteI liked article. But MFR is required for APi also???

ReplyDeleteI liked this side sir but i required BPR sample

ReplyDeleteGood information....

ReplyDeleteThank you Sir!

ReplyDeleteThanks

ReplyDeleteWhich guidelines are used for mfr preparation

ReplyDeleteGreat

ReplyDeleteThanks sir

ReplyDelete