All pharmaceutical companies have established strict guidelines and regulations according to current good manufacturing (cGMP) guidelines. These guidelines help the manufacturers to ensure the quality of manufactured pharmaceutical products. Despite these efforts by the companies, there are a lot of issues found during regulatory inspections. This article will explore some of the most common GMP violations and their impact on the pharmaceutical industry.

The main reason is that companies are focusing on cost cutting. In cost cutting, they skip the safety measures that lead to the GMP violation. In addition, some companies are less aware abut the GMP and regulatory guidelines and they bypass the actual process.

The solution is to increase the frequency of inspection by the regulatory agencies. More frequent inspection will help to maintain the GMP regulations in manufacturing facilities. In addition, companies should ensure that their employees are fully aware of GMP regulations and they strictly follow these. Companies should make strict rules for GMP violations in facility.

As the pharmaceutical industry is growing, the number of GMP violations is also increasing. If you are aware of the occurrence of GMP violations in your company, you can take the necessary steps to prevent them from happening. By preventing the GMP violation you can ensure that your company is in compliance with the regulatory requirements.

What are Good Manufacturing Practices Violations?

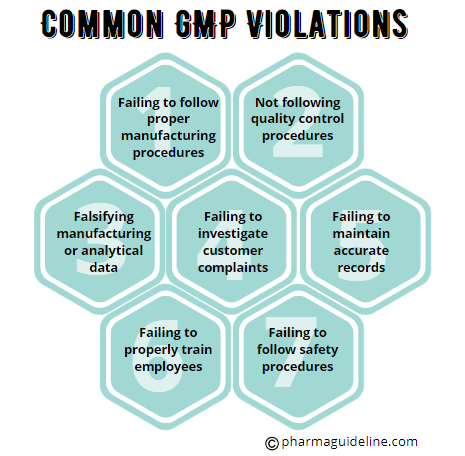

GMP is a set of guidelines that must be followed by the pharmaceutical companies to manufacture the pharmaceutical products. The most common GMP violations are deviations from good manufacturing practices in manufacturing and record keeping. These violations can have serious consequences for the manufacturers; therefore, it is critical to follow all procedures correctly.Types of GMP Violations

Some pharmaceutical manufacturing companies fail to follow good manufacturing practices in different ways. Some of the most common problems include:1. Not Following Proper Manufacturing Procedures

This is the most common and frequent GMP error that has various reasons. For example, in sterile manufacturing, if any equipment or utensils are not properly sterilized that can lead to contaminate the whole match.2. Not Following Quality Control Protocols

Quality control helps to analyze the product for its quality. It ensures that the product meets the quality and safety standards. If quality control procedures are not followed correctly, it can result in the production of substandard products.3. Falsifying Data

Falsifying data in any stage of manufacturing from raw material to finished product release is a serious GMP violation. Companies do it to save time or hide the mistakes during manufacturing of quality control analysis. Falsification of data in quality control analysis is very common.4. Failing to Investigate Customer Complaints

It is mandatory to investigate the customer complaints received from the market. Some companies ignore these complaints which leads to more issues resulting in product recalls.5. Failing to Maintain Accurate Records

In pharmaceutical companies, documents must be complete, accurate and up to date from raw material to finished product. Failing to maintain accurate records creates serious issues and harder to fix problems when they arise.6. Failing to Properly Train Employees

Training of employees is the most important aspect of GMP regulations. Proper training is important to understand and follow the manufacturing procedures correctly. Untrained employees make errors during manufacturing that create GMP violations.7. Failing to Follow Safety Procedures

Employees must be trained for proper handling of equipment and materials. Untrained employees will work in the wrong way and create errors resulting in production of substandard products.How Common are GMP Violations?

GMP violations are very common in the pharmaceutical industry. The occurrence of GMP violations is increased recently. According to the FDA GMP violations have increased by 54% in recent years. There are many reasons behind this increase.The main reason is that companies are focusing on cost cutting. In cost cutting, they skip the safety measures that lead to the GMP violation. In addition, some companies are less aware abut the GMP and regulatory guidelines and they bypass the actual process.

What can be done to Prevent GMP Violations?

Implementation of GMP regulations is important to avoid the contamination in pharmaceutical products. All pharmaceutical companies follow GMP regulations but still the GMP violations are increased in recent years. What can be done to prevent these violations?The solution is to increase the frequency of inspection by the regulatory agencies. More frequent inspection will help to maintain the GMP regulations in manufacturing facilities. In addition, companies should ensure that their employees are fully aware of GMP regulations and they strictly follow these. Companies should make strict rules for GMP violations in facility.

As the pharmaceutical industry is growing, the number of GMP violations is also increasing. If you are aware of the occurrence of GMP violations in your company, you can take the necessary steps to prevent them from happening. By preventing the GMP violation you can ensure that your company is in compliance with the regulatory requirements.

Get documents for Audit preparation in MS-Word FormatView List

No comments:

Post a Comment

Please don't spam. Comments having links would not be published.